Types of metal 3D printing methods

작성자

MERAIN

작성일

21-11-08 12:54

조회수

2,182

본문

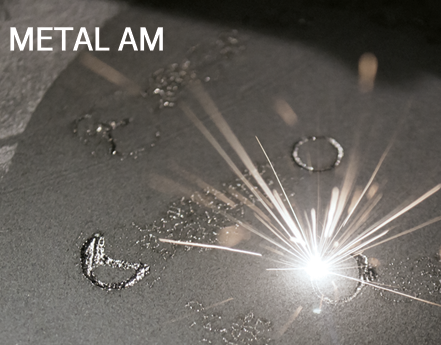

AM (Additive Manufacturing)

The method of stacking and printing materials in layers is called the additive processing method (AM).

There are various AM methods depending on the material and the molding technology.

In 3D printing, metal handling methods include PBF and DED methods that melt metal powders with high-power lasers,

The BJ method is a method of bonding one by one with a binder and making it through a heat treatment process.

It's made by stacking it with ceramic materials and sintering it later.

There are many ways, but what we have in common is the concept of stacking.

You can make it in the necessary way considering the material, precision, business field, volume or size.

If I summarize metal 3D printing into three categories,

1. Concept that contrasts with cutting processing that cuts or cuts materials.

2. The degree of freedom in design is very high, increasing the efficiency of development and prototype production.

3. Specialized in producing high value-added products in small quantities of various varieties.

Summary: Melt the metal powder by selectively irradiating and melting the metal powder material with a high-power laser.

Advantages: It is good for manufacturing precise parts, small parts, etc.

Weakness: Powder is usually expensive because of its small particle size.

The PBF method has the best precision and is widely used among metal 3D printing methods.

It is advantageous to manufacture precise parts.

The disadvantage is that it takes a long time to print and the metal powder has a small particle size and a high price.

It is suitable for high value-added products with a small amount of variety.

Summary: Spray the powder at high pressure -> directly deposit the powder with a high-power laser and melt it.

Advantages: The price of the powder is low. The particle size is 100-150um. You can add it to the existing shape.

Disadvantage: The precision is lower than that of the PBF method, and it is difficult to produce a small and precise shape.

The DED method is a method of spraying and depositing powder with a high-pressure axis and melting it with a laser at the same time.

The speed is fast and the price of the powder is relatively low. You can add it to the existing shape to make it.

It is good for maintenance of parts. It is difficult to make small and precise shapes.

Summary: A method of spraying a binder onto a thin layer of powder material to deposit (ExOne)

Advantages: There is no deformation due to thermal stress, and it is printed one by one as if drawing, so the speed is fast.

Disadvantage: The mechanical properties are poor, and the thermal treatment process is difficult and important.

It is not difficult to understand when you think of an inkjet printer by spraying a binder (bond) on a thin layer of powder material and depositing it.

Since it is not a method of melting with a laser, there is little deformation due to thermal stress generated during the lamination process and the manufacturing speed is fast.

However, the biggest disadvantage of the BJ method is the heat treatment process. It is safe to say that it starts with heat treatment and ends with heat treatment.

In the heat treatment process, the design shall be carried out in light of shrinkage, and complicated and difficult shapes shall be designed in consideration of shrinkage.

Shrinkage reinforcement design is required. Interpretation is very important.

There are also various other metal 3D printing methods.

Metal 3D printing has various processes depending on the material and purpose, so you have to find a way suitable for the purpose of use.

- If you need to make precise parts that are important in terms of dimensions, use PBF method.

- It's not precise, but if you need a certain amount, use desktop metal or BJ.

- If you need to maintain the damaged parts or add metal workpiece to a certain surface, the DED method.

Lastly, the most important thing in metal 3D printing is post-processing.

We will deal with the details of post-processing later.

Thank you.

- 이전글DfAM(Design for Additive Manufacturing) 21.11.08

- 다음글File format covered by Magics #01 Magics 21.11.08