본문

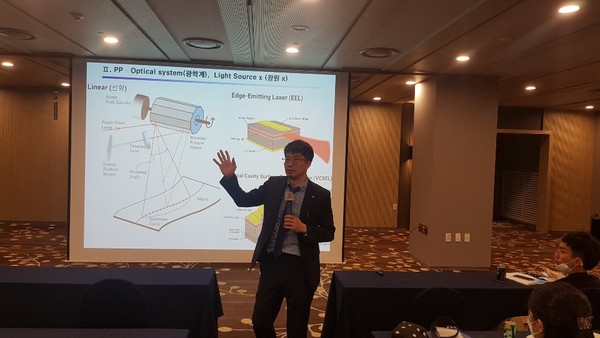

▲ Shin Jin-guk, head of the business group, is presenting the 3D printing mechanism at a general workshop on fostering 3D printing professionals based on high-tech new materials.

The "High-tech New Material-based 3D Printing Professional Training Project," which trains master's and doctorate-level R&D experts with core and application technologies related to 3D printing to contribute to manufacturing innovation in major industries such as medical, automobile, and shipbuilding, will strengthen customized and online education.

The Electronic Parts Research Institute, which oversees the "high-tech new material-based 3D printing professional training project" being promoted by the Ministry of Trade, Industry and Energy, held a "general workshop in the first half of the third year" at Lahan Hotel Jeonju from the 20th to the 22nd. About 80 professors and master's students from Ulsan University, Jeonbuk National University, Dankook University, Kyungpook National University, and Inha University attended the workshop.

The "High-tech New Material-based 3D Printing Professional Training Project" aims to cultivate 40 master's and doctorate R&D professionals annually and link them to employment and start-ups, which will contribute to innovation in major industries such as medical, automobile, and shipbuilding.

In particular, 3D printing convergence education is conducted based on new metal, plastic, smart, bio/medical materials that are the core of 3D printing technology and are in high demand in the industry. Each university participating in the project operates master's and doctorate education focusing on specialized 3D printing materials. Ulsan University is in charge of metal materials, Jeonbuk National University is in charge of smart materials (phopolymer), Dankook University is in charge of plastic materials, Korea University of Industrial Technology is in charge of bio and medical materials, Kyungpook National University is in charge of medical devices, and Inha University is in charge of special metal materials. About 10 professors from each university participate to support education.

The professional manpower training project, which marks its third year this year, had difficulty in conducting theoretical and practical education as planned due to social distancing caused by the spread of COVID-19 in the first half of the year. The project group plans to focus on education, which has been delayed as COVID-19 calms down, while strengthening customized education and online education.

As part of this, companies or institutions will transport equipment to universities by changing the method of practical training that used to be conducted by visiting companies or institutions with infrastructure such as 3D printers. It is expected that the educational effect will be great as customized education is provided to students with the same field of interest.

In addition, in order to effectively conduct online education in line with the era of untact accelerating post-COVID-19, it will develop online educational content and platform, online industry-academic projects and field practice performance management, and improve the online history management system for non-face-to-face employment support.

This year's online training is planned to be carried out on a trial basis by manufacturing 3D printer equipment such as FDM, PBF, and PP, as well as materials such as powders, filaments, and photocurable resins. It also plans to increase the employment rate by producing an online job-tailored video portfolio of prospective graduates in line with the trend of converting employment, one of the main purposes of the project, into non-face-to-face.

Shin Jin-guk, general manager of the project, said, "The main purpose of our project is to increase students' insight through the process of solving challenges on our own, and this is an essential ability in the current situation where COVID-19 and the 4th industrial revolution are faster and more uncertain."

Meanwhile, officials from Seoul National University, Samyoung Machinery, Korea DIC, and Inha University gave in-depth lectures on 3D printers and materials such as metals, plastics, and ceramics to enhance their understanding of 3D printing.

Sung Yoo-chul, head of DIC Korea, said in a theme presentation on 'Materials, Principles, Types, and Usage used in FDM and PP (Photo-curing Resin), "Photo-curing Resin is widely used in our flagship industries, semiconductors and displays, so Korea is likely to dominate the 3D printing resin market."

Lee Ki-an, a professor at Inha University, announced "Metal 3D printing powder and materials," saying, "Currently, cheaper and faster metal 3D printing processes are being developed around the world, and in order to expand the market in the future, low prices must be carried out along with R&D."

Sung Yoo-chul, head of DIC Korea, is announcing "materials, principles, types, and usage methods used in FDM and PP."